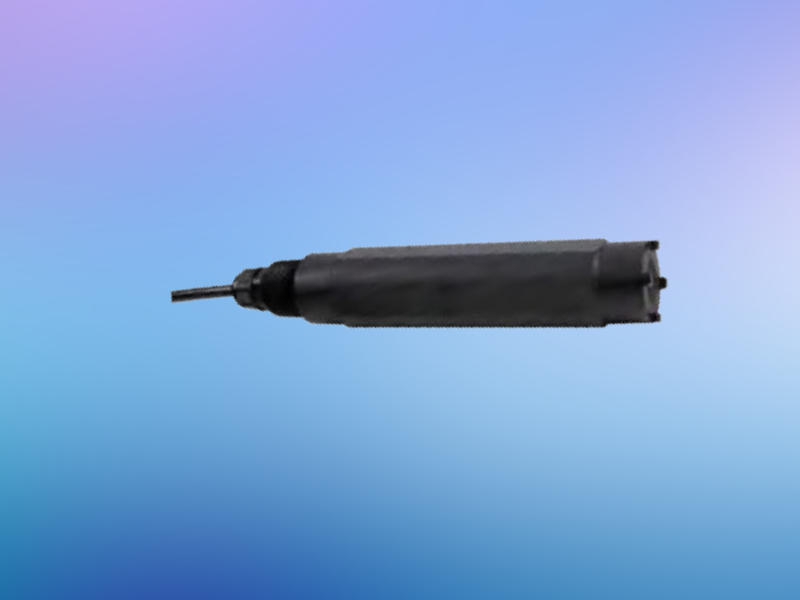

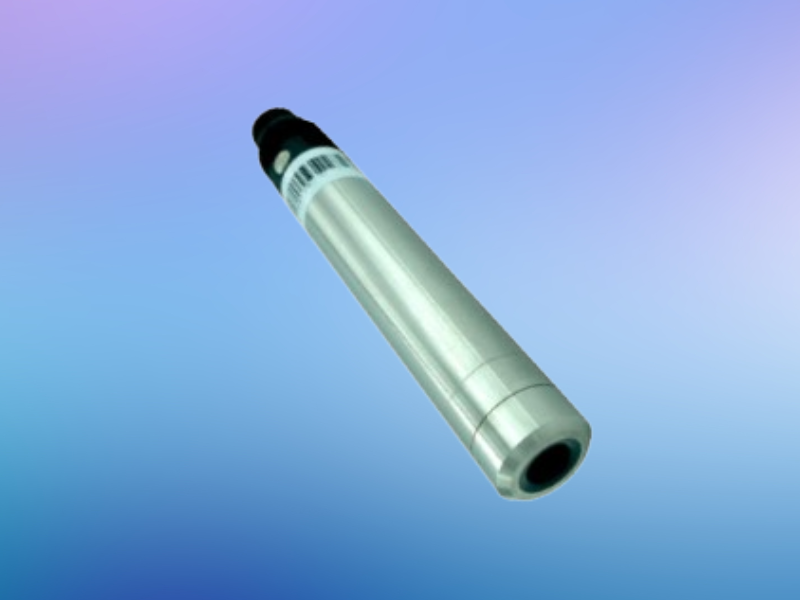

Digital Fluorescent Dissolved Oxygen Sensor BH-DY12

The Digital Fluorescent Dissolved Oxygen Sensor BH-DY12 quenching detection technology to convert the optical signal of the interaction between oxygen molecules and fluorescent molecules into

electrical signals. Through 3D algorithms, stable and sensitive oxygen concentration or oxygen partial pressure changes are obtained. Compared with the second generation electrochemical measurement

technology, the LH-DY12 fluorescent dissolved oxygen sensor measures higher, is plug-and-play and does not require the addition of any chemical reagents. It is an ideal choice for industries such as chemical industry, biomedicine, nuclear power, sewage and wastewater treatment, and smart aquaculture. Ideal for water quality testing.

Feature Digital Fluorescent Dissolved Oxygen Sensor BH-DY12

| Measuring Range | Dissolved Oxygen: 0-25mg/L |

| Saturation: 0-250% | |

| Working temperature: 0-55℃ | |

| Working pressure: 0-150k Pa | |

| Accuracy | Dissolved Oxygen: ±0.1mg/L or ±1% (0-100%) ±0.2mg/L or ±2% (100-250%) |

| Temperature: ±0.1℃ | |

| Pressure: ±0.2kPa | |

| Dissolved Oxygen Compensation | Temperature: 0-50℃ automatic compensation |

| Pressure: Instrument side program or manual | |

| Salinity: instrument program or manual | |

| Calibration | One point calibration: saturation 100% |

| Two-point calibration: 1st point saturation 0% (zero oxygen water) 2nd point saturation 100% | |

| Response Time | Saturation: T90<60s (saturation drops from 100% to 10%) |

| Storage Temperature | 20-80℃ |

| Waterproof Level | Fixed installation: IP68 Underwater sinking: up to 100 meters |

| Working Power Supply | DC power supply 12-36 VDC (current ≥50mA) |

| Power Consumption | ≤40mA (12V DC power supply) |

| Data Output | Digital signal MODBUS-RS485 Analog signal 4-20mA, 0-5V (optional) |

| Material | Diaphragm cap: PVC/PMMA Shell: PVC (other options are PP/PPS/titanium alloy) |

| Rated Power | <0.5W |

| Installation Method | 3/4NPT pipe thread installation at the end |

| Wire Length | Standard 10 meters (other options are 5, 20-200 meters) |

| Warranty | Diaphragm cap: 1 year (normal maintenance) Shell: 2 years (normal use) |